How Do LEDs Work? A Quick Primer on LED Lighting Technology

Leave a CommentOne of the most popular acronyms in the lighting design world and around the GPI Design office is “LED”. So what does it stand for, and how do LEDs work? While not an exhaustive investigation, this blog post will give you a primer on LED lighting technology and how LEDs work.

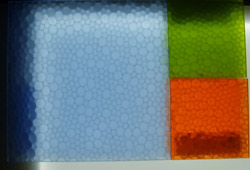

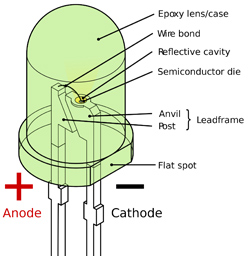

An LED, or Light Emitting Diode, is a semiconductor light source. When an electrical current flows through the diode, electrons in the current experience an energy drop. During this drop, energy is released in the form of light. LEDs emit different colors due to different energy drops or due to a coating on the LED. That’s how GPI can offer different lighting solutions with colors like white, red, blue, yellow, and more. LEDs are extremely efficient, last longer than traditional light sources, and are capable of producing clearer, crisper light. LEDs are gradually replacing older forms of lighting, including incadescent bulbs and florescent bulbs, and are quickly becoming the light of the future.

So how exactly does an LED work?

1. An LED is hooked up to an energy source.

2. An electrical current flows from the positive terminal, through the diode, and out the negative terminal.

3. An electrical current is composed of electrons. The electrons, when flowing through the diode, drop down to a lower energy state.

4. During the drop, energy is released in the form of photons, or small packets of light.

5. The light bounces around in the plastic shell of the LED, and then escapes as visible light.

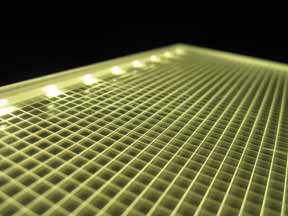

An LED gets its energy from a low, constant DC voltage. An individual LED requires 2-4V of DC power and several hundred mA of current. LEDs connected in series as part of an array require higher voltage. In order to get the correct DC voltage, LEDs require drivers, which convert incoming AC power to the proper DC voltage and regulate the current. Thus, a driver is considered the power supply of LEDs. To control LEDs and achieve affects like dimming or color changing, different controllers are used.

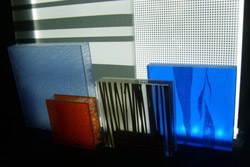

While it seems like there are many parts to LED systems- drivers, controllers, bulbs, panels, scrims- our Infuse™ Complete LED Backlighting System brings them all together to achieve beautiful backlit features with complete LED backlighting systems.