7 Reasons Why Flat LED Lighting Panels Are Imperfect Products

Flat LED panels are new technology, and if you’re a designer or architect you are probably aware of a handful of manufacturers that produce these products. And while many of the physical characteristics of LED panels are the same across the board, the majority of manufacturers lack the expertise to implement the panels with actual surfaces in actual construction environments. Here are some considerations when specifying flat LED panels for commercial projects:

1. Hot spots

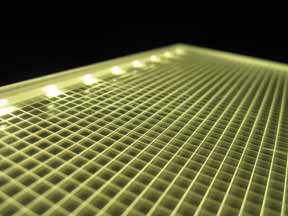

Edge lit LED panels are manufactured by embedding energy-efficient, high output LEDs along the edges of a thin acrylic panel. Laser-etched channels distribute light across the face of the panel. There is often a bright line at the edge of the panel where the actual light source is located. This bright line can transfer through the surface being backlit, disrupting the visual continuity of the surface.

2. Difficult to determine how many edges to run LEDs across

If engineered incorrectly, too many LED strings will result in bright panels with excessive hot spots at the edges. Too few LED strings will cause cold spots at the unlit edges and possibly towards the center of the panel.

3. Cold spots

If panels are sized incorrectly or LED strings run on the wrong sides of the panel, the light source may not sufficiently transfer across the entire face of the panel, resulting in cold spots towards the center of the panel.

4. Expensive

The up-front cost of LED technology is expensive, and it can be difficult for architects and interior designers to convince clients to invest in high-end products.

5. Imperfections in acrylic batches

Acrylic production results in slight variations between batches; this is very typical for the acrylic industry, but when you add light to the mix, the imperfections are exaggerated.

6. Powering every single panel with an adapter

Not a problem if you’re designing a backlit bartop for a residence, but when designing large commercial features, plugging each individual panel into an outlet is inefficient (and quite ridiculous, if you ask us!).

7. Varying panel sizes have varying brightness

Depending on the proportion of the panels (long rectangles or even squares), smaller LED panels will appear brighter than larger panels. This is due to light bouncing in a decreased area, and also because of the voltage drop that occurs over the longer LED strands.