Interior Finish Products: Fire Safety and Flame Spread- What Does It All Mean?

As an integrated engineering, design, and supply firm, we frequently work with suppliers, engineers, designers, and architects to provide our unique backlit onyx features. One topic that seems to be shrouded in mystery is the topic of fire safety and fire requirements. Terms are frequently confused or misused, and data is often difficult to find (if it even exists). So what are the different areas of fire safety? What guidelines or codes do you have to follow?

First off, every country, and sometimes even city, has its own building codes that specify certain safety requirements in structures. In the U.S., the most frequently used code is the IBC, (International Building Code) which is put forth by the ICC (International Code Council).

To meet these requirements, certain standards and tests must be carried out. To this end, technical standards are written that dictate a list of requirements that must be met. These technical standards, or specifications, can be written by private companies, government agencies, or standards organizations- ASTM, ISO, CEN, etc.

Those are the basic terms, for those unacquainted with building codes and standards. Onward to the flames! There are two major categories of fire safety ratings. First there is fire resistance. Fire resistance deals with the ability of structural components (walls, floors, ceilings, doors) to restrict the spread of flame and maintain structural integrity in a fire. Fire resistance relates to structural fire performance and becomes important after a fire has started and threatens a building’s structural integrity. The fire resistance test method used throughout the United States is ASTM E 119, Standard Test Methods for Fire Tests of Building Construction and Materials. Fire resistance is usually measured in hours that the material or structure withstands the flame of a certain temperature.

However, not everything in a building must be tested for fire resistance. Interior finishes and exposed materials- wall coverings, ceiling finishes, etc.- are usually tested for flame resistance. Flame resistance deals with the potential for fire growth within a structure. Instead of fire resistance, which describes the performance of materials once a fire has already started, flame resistance measures properties in the early stages of a fire. There are several categories within flame resistance; most notably flame spread index and smoke-developed index.

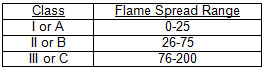

The flame spread index (FSI) measures how quickly a flame propagates, or moves, across a surface. Materials are assigned values in the U.S. using a test known as ASTM E-84, Standard Test Method for Surface Burning Characteristics of Building Materials. Materials are measured on a scale of 0-1000. A low FSI indicates a low burn rate. Thus, 0 is calibrated to noncombustible materials (i.e. concrete) while 100 is calibrated to 23/32” red oak flooring. Classification in codes are:

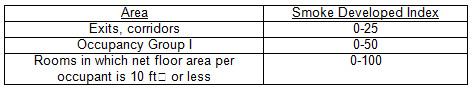

The smoke-developed index (SDI) measures the concentration of smoke given off as a material burns. The index ranges from 0-450, and a low SDI indicates a low smoke development rate.

Depending on the local codes, building occupancy, and intended building use, different requirements and levels of performance will be needed. And here at GPI Design, our team of designers, engineers, and architects will work with you to achieve a beautiful LED backlit onyx feature that will meet the codes- and exceed your expectations!