Creating Continuous LED Backlighting: 4 Types of Light Seams to Consider

Natural sunlight is a seamless light that provides enveloping spatial qualities, free from interruption. With designers increasingly turning to nature for design inspiration, recreating this smooth quality can be tricky with artificial lighting technology. How do you avoid choppy, spotty, discontinuous appearance within your artificial lighting sources?

When translating your design from small samples to fully cladding an entire wall, don’t forget that the every material has its scalar limits. (Yes, even LED light panels are limited to 4’ x 9’ sheets!) This means that for a cladding a 10’ x 40’ backlit glass wall, you could have anywhere from 11 to 100 individual LED light panels, and probably only 8 glass panels. How do we make those seams in the lighting disappear? It depends on the specific condition and how the Flat-Lite™ LED panels are designed. At GPI, we use these terms to qualify what type of light seam we are designing around:

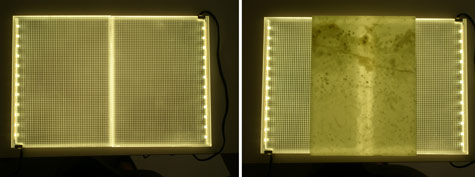

1. Non-powered field seam

Non-powered field seam condition without diffusing methods or correct cavity

This type of edge does not have LEDs located on it, but when light bounces off the edge of the panel, a slight bright spot still occurs. When non-powered field seams are located in the center (or “field”) of the surface panel, it can become apparent. Calculating the correct lighting cavity (situating the surface the correct distance away from the light source) typically mitigates the evidence of a non-powered field seam.

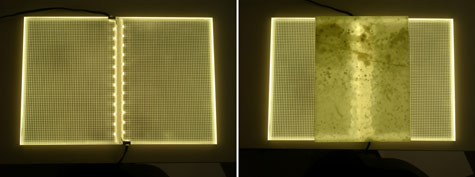

2. Powered field seam

Powered field seam condition without diffusing methods or correct cavity

Powered field seams are the illuminated edge along which the LED light sources are located. These are the brightest and most susceptible of seams. When butted together and placed behind the center of a continuous surface panel (glass/resin/stone/fabric), powered field seams can create a very evident bright line. Without finish trims and edge treatments to disguise the bright line, their location within the center continuous surface makes them even more apparent. Diffusing panels and optic films are often applied to the Flat-Lite™ LED panels to disguise the evidence of a powered field seam.

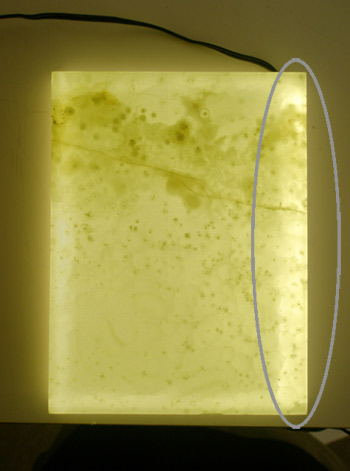

3. Powered perimeter

In gray circle: powered perimeter without any diffusing methods

A powered perimeter is an edge with LED light sources located around the perimeter of your feature (where it meets the wall, ceiling, or finish trim). The powered edge seam doesn’t fall in the middle of a glass or onyx panel, so it doesn’t appear as disruptive as #2, but can provide evidence of bright spots.

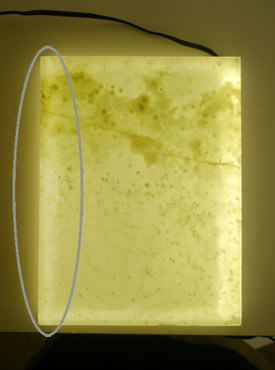

4. Non-powered perimeter

In gray circle: non-powered perimeter without any diffusing methods

The non-powered perimeter is our best friend. This condition does not contain LED light sources and is usually tucked away. When all of the other conditions are diffused, it typically fades away quietly into the background, with little attention needed.

–> Don’t think that testing with one small lighting sample that appears continuous in a small square means your design work is done. Pay careful attention when translating the lighting design to full scale panels, with particular attention to how the lighting panels meet at seams and match up with your surface module sizes.